Nice to meet you :)

Alpha Line Lab Business, a laboratory safety integrated management company.

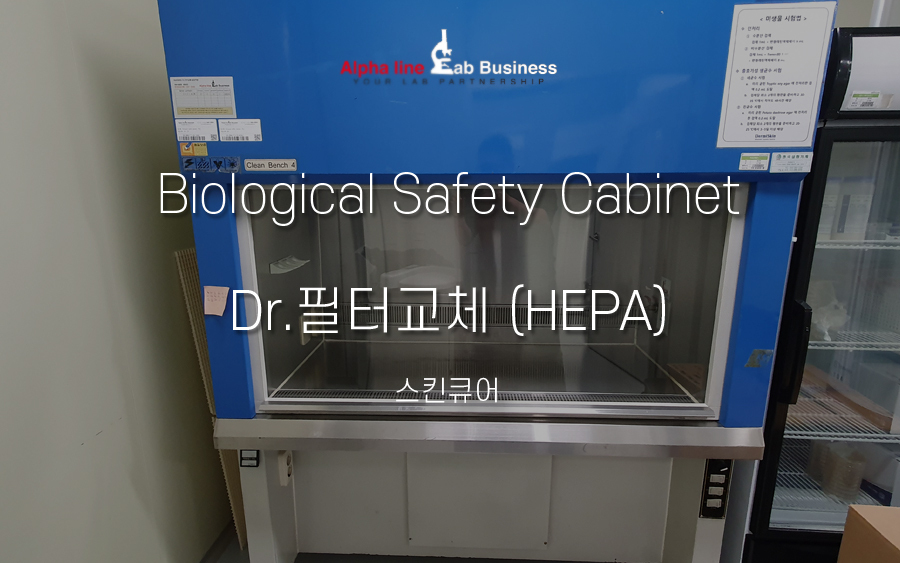

The most important thing in the safety management of BSC safety management

A key filter replacement for the BSC.

The biological safety workstation is an equipment for protecting samples and workers together, and the HEPA filter is

Periodic filter replacement checks are required because you must always maintain the best condition.

Replace Dr. Filter (HEPA Filter)

In the filter comparison picture, it was possible to visually see that the color of the filter that was replaced was changed,

Since there is no pre-filter in charge of preprocessing, the contamination rate is slightly faster than that of the clean bench.

The accumulation of particles in the filter can lead to contamination, and the accumulated pollutants interfere with the flow of air, reducing the internal wind speed

It may compromise the cleanliness of the inside of the equipment.

For integrated safety management, we measure and check airflow, wind speed, particulate matter, balance, illumination, noise, etc. and provide the result value as a report

If you replace the filter, we offer the Simple Validation free of charge.

We will also check for air leaks that may occur in equipment gaps.

Occasional leakage of air interferes with the flow of air in the equipment, and the wind speed is

Weakness and clean air do not flow smoothly,

In order to manage this, we proceed with equipment repair through reform.

Biological Safety Workstation BSC (Biological Safety Cabinet/Class IIA2 Type)

Biological Safety Workstation BSC (Biological Safety Cabinet)

Unlike the clean bench, the BSC has a working air (air pollution) in the direction of the operator

It is a workstation used to protect both the sample and the worker with a structure

that does not come out directly.

The characteristic airflow in the BSC of the bio-safety workstation is the lower part of the front window of the workstation

Repeat circulation and discharge by filtering the indoor air introduced into the perforated holes in the air chamber

where the filter is installed through the internal passage.

Among them, the A2 type is widely used, and it is a model that is widely used in research experiments based on BL2 and 3rd grade handling standards.

The A2 type does not require a separate duct with a 70% circulation and 30% exhaust for 100% air inflow.

As the purpose of BSC is equipment that handles harmful bacteria and viruses, in order to ensure the user's safety

It is recommended that you choose proven products with

strict international certification such as EN12469, UL, NSF, and ANSI.

When purchasing and using a product that is called a biological safety workstation but has not obtained international certification just because it is inexpensive

It is not completely protected from harmful bacteria and viruses, which can lead to infection concerns,

In the future, a validation (qualification) will be conducted, and the rating may be inappropriate due to insufficient performance.

Therefore, unlike clean benches, BSCs are designed to prevent workers from being exposed to contaminated air as much as possible, so even if they handle bacteria or microorganisms

Because it can prevent infection (contamination), it is much safer than a clean bench in terms of versatile experiments.

'Alpha Line Lab Business' uses the same equipment as GMP certification for free simple validation, and all completed calibration certification on March 14, 2023, so the measurement results can be trusted.

Simple Validation

In 'Alpha Line Lab Business', when changing filters,

Simple Validation is provided free of charge.

<UNT_PHL> Simple Validation is an item that is equivalent to IQ.OQ for the

purpose of managing its own equipment

Installation environment, noise, illumination. Measurement of horizontality, airflow, falling wind speed, particles, etc

We will provide you with the results in a report.

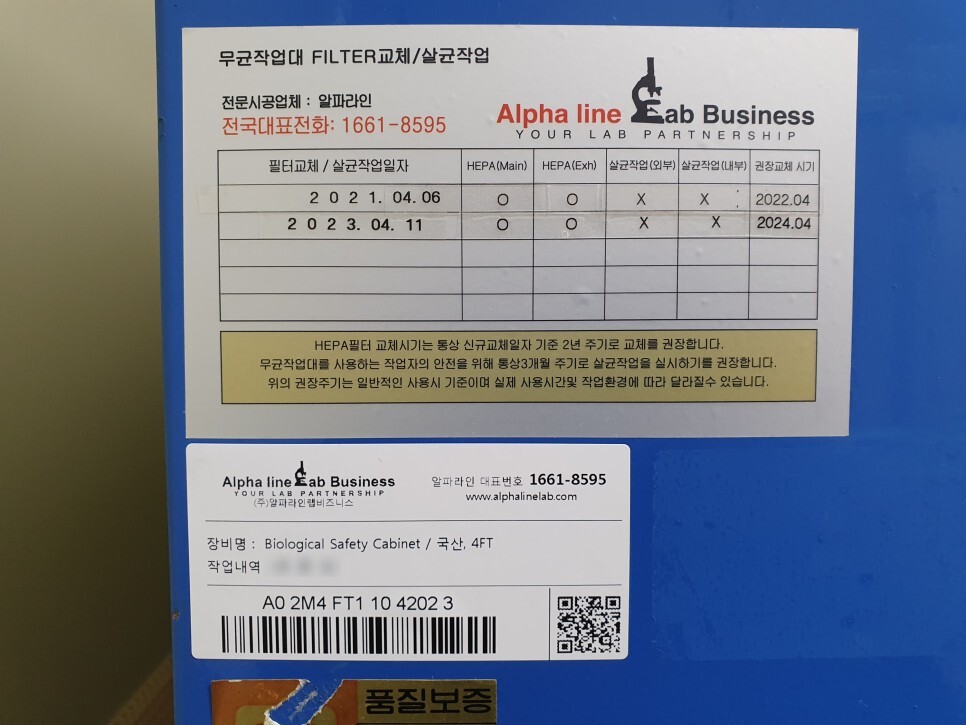

When the filter replacement, validation, and sterilization care are all completed, the work history will be attached.

The work history records what you have been managed through the Alpha Line Lab business, so you can see the management history of the equipment at a glance

We will help you with systematic management in the future with the unique number of the Alpha Line Lab business that is written along with the management history.

All fieldwork is accompanied by a professional, knowledgeable and experienced Field Manager

Follow the safety guide manual to manage and supervise the entire operation.

Although the laboratory uses a bio-safety workstation, it is true that it is difficult to manage it by the laboratory.

In fact, there are many laboratories that are experiencing contamination and are having difficulty

They are thinking a lot to find the cause of contamination.

Solutions to contaminated situations in Biological Safety Cabinet that should remain sterile

1. Periodic replacement of HEPA Filter

The filter has never been replaced or has passed the replacement period

2. Periodic cleaning operation

Pollutants are piled up inside the equipment and stuck, causing bacteria to reproduce.

3. Periodic sterilization work

Fungus and viruses live in places that are not easily visible.

4. Equipment inspection and repair replacement required

The older the equipment, the more necessary it is to inspect it, and if it has lost its function, it is time to replace it.

Experimental equipment can be used safely and for a long time through periodic inspection management!

Continuous management as above can minimize equipment

failures and improve the environment and quality of the laboratory

Remember, you can save money on expensive equipment!

Blog : https://blog.naver.com/alphalinelabbiz

Tell : 1661-8595

E-Mail : alphalinelab@gmail.com